Nikiforov

Vladimir O.

D.Sc., Prof.

doi: 10.17586/2226-1494-2016-16-6-1010-1017

INKJET PRINTING OF HIGH REFRACTIVE STRUCTURES BASED ON TiO2 SOL

Read the full article

For citation: Eremeeva E.A., Pidko E.A., Vinogradov A.V., Yakovlev A.V. Inkjet printing of high refractive structures based on TiO2 sol. Scientific and Technical Journal of Information Technologies, Mechanics and Optics, 2016, vol. 16, no. 5, pp. 1010–1017. doi: 10.17586/2226-1494-2016-16-6-1010-1017

Abstract

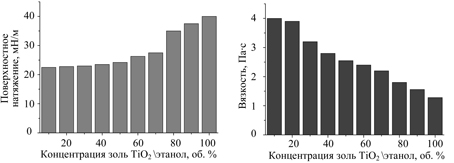

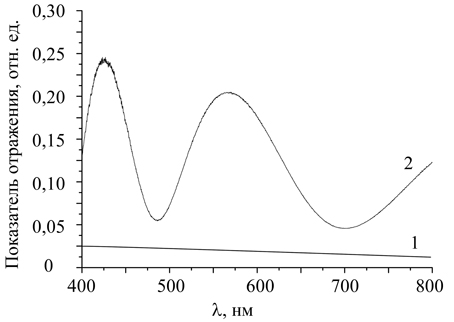

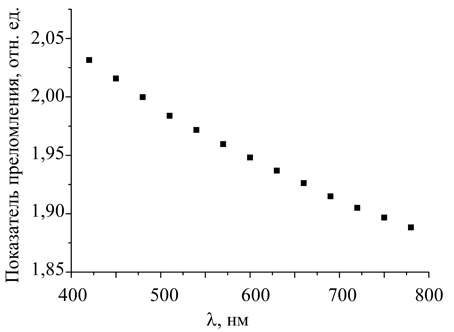

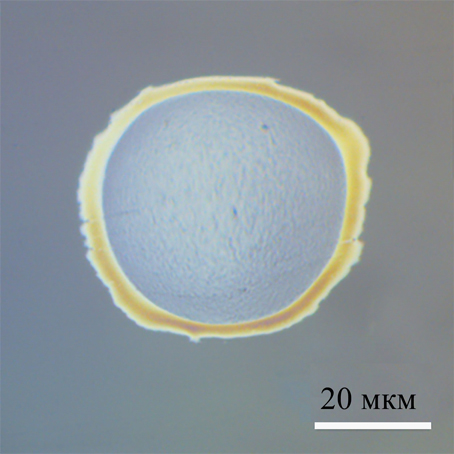

Subject of Research. The paper deals with description of novel inkjet printing method for optical elements formed by structures based on TiO2 sol. The proposed approach presents effective way to obtain such optical nano objects as diffraction structures and transparent interference patterns. Methods. TiO2 nanoparticles were synthesized by hydrolysis of titanium isopropoxide (0.36 mol) in deionized water (33.3 mol) under vigorous stirring and using nitric acid (0.04 mol) as a protonating agent. Viscosity was determined by Brookfield HA/HB viscometer, and surface tension - by Kyowa DY-700 tensiometer. Titanium dioxide inks were deposited on commercially available microembossed PET film with a thickness of 20 µm. To print titania ink Canon Pixma IP 2840 desktop office printer was used with a drop volume of 2 pL. The thickness of an inkjet TiO2 layer after drying in the air and removal of the solvents did not exceed 500 nm with a refractive index not less than 2.08 in the entire visible range.Main Results. The synthesis of aqueous TiO2 sol was used to obtain the ink with desirable rheological characteristics: viscosity and surface tension. The required rheology was regulated by controlling parameters of sol-gel transition in the system of aqueous titanium dioxide sol and by adding ethanol that affects the charge of double electrical layer of disperse phase. The reviled ratio of titanium dioxide sol and ethanol in the system gives such values of viscosity and surface tension that make this material convenient for inkjet printing. The coatings created by sol have a high refractive index in the entire visible range (not less than 2.08). We have shown that the deposition of optical transparent microstructures with diffraction effect has an ability to be applied on the transparent surfaces. The morphology of particles and the topology of printed structures were analyzed by optic and atomic-force microscopes.Practical Relevance. We have proposed the approach to obtain colorful interference patterns using one type of high refractive inks. The method opens new opportunities for “roll-to-roll” production technology of protected optical structures on the flexible polymer substrates.

References

1. Yakovlev A.V., Milichko V.A., Vinogradov V.V., Vinogradov A.V. Sol-gel assisted inkjet hologram patterning. Advanced Functional Materials, 2015, vol. 25, no. 47, pp. 7375–7380. doi: 10.1002/adfm.201503483

2. Calvert P. Inkjet printing for materials and devices. Chemistry of Materials, 2001, vol. 13, no. 10, pp. 3299–3305. doi: 10.1021/cm0101632

3. Singh M., Haverinen H.M., Dhagat P., Jabbour G.E. Inkjet printing-process and its applications. Advanced Materials, 2010, vol. 22, no. 6, pp. 673–685. doi: 10.1002/adma.200901141

4. Yakovlev A.V., Milichko V.A., Vinogradov V.V., Vinogradov A.V. Inkjet color printing by interference nanostructures. ACS Nano, 2016, vol. 10, no. 3, pp. 3078–3086. doi: 10.1021/acsnano.5b06074

5. Hebner T.R., Wu C.C., Marcy D., Lu M.H., Sturm J.C. Ink-jet printing of doped polymers for organic light emitting devices. Applied Physics Letters, 1998, vol. 72, no. 5, pp. 519–521. doi: 10.1063/1.120807

6. Zhang S. Fabrication of novel biomaterials through molecular self-assembly. Nature Biotechnology, 2003, vol. 21, no. 10, pp. 1171–1178. doi: 10.1038/nbt874

7. Liu J-G., Nakamura Y., Ogura T., Shibasaki Y., Ando S., Ueda M. Optically transparent sulfur-containing polyimide-TiO2 nanocomposite films with high refractive index and negative pattern formation from poly(amic acid)-TiO2nanocomposite film. Chemistry of Materials, 2008, vol. 20, no. 1, pp. 273–281. doi: 10.1021/cm071430s

8. Lv C., Liu Y., Mo J., Li P., Lv X. Angle-resolved diffraction grating biosensor based on porous silicon. Journal of Applied Physics, 2016, vol. 119, no. 9, art. 094502. doi: 10.1063/1.4943072

9. Lee L.-H., Chen W.-C. High-refractive-ondex thin films prepared from trialkoxysilane-capped poly(methyl methacrylate)-titania materials. Chemistry of Materials, 2001, vol. 13, no. 3, pp. 1137–1138. doi: 10.1021/cm000937z

10. Elim H.I., Cai B., Kurata Y., Sugihara O., Kaino T., Adschiri T., Chu A.-L., Kambe N. Refractive index control and rayleigh scattering properties of transparent TiO2 nanohybrid polymer. Journal of Physics Chemistry B, 2009, vol. 113, no. 1, pp. 10143–10148. doi: 10.1021/jp902598f

11. Cavallin T., Habra N., Casarin M., Bordin F., Sartori A., Favaro M., Gerbasi R., Rossetto G. Superhydrophilic and tribological improvements of polymeric surfaces via plasma enhanced chemical vapor deposition ceramic coatings. Journal of Nanoscience and Nanotechnology, 2011, vol. 11, no. 9, pp. 8079–8082. doi: 10.1166/jnn.2011.5084

12. Szili E.J., Kumar S., Smart R.St.C., Lowe R., Saiz E., Voelcker N.H. Plasma enhanced chemical vapour deposition of silica onto titanium: analysis of surface chemistry, morphology and functional hydroxyl groups. Surface Science, 2008, vol. 602, no. 14, pp. 2402–2411. doi: 10.1016/j.susc.2008.05.027

13. Wu J. Computer Generated Hologram. Available at: http://www.loft.optics.arizona.edu/documents/journal_articles/2007_James_Wu.pdf (accessed 28.09.2016).

14. Vinogradov A.V., Vinogradov V.V. Effect of acidic peptization on formation of highly photoactive TiO2 films prepared without heat treatment. Journal of the American Ceramic Society, 2014, vol. 97, no. 1, pp. 290–294. doi: 10.1111/jace.12560

15. Gao L., Lemarchand R., Lequime M. Refractive index determination of SiO2 layer in the UV/Vis/NIR range: spectrophotometric reverse engineering on single and bi-layer designs. Journal of the European Optical Society. Rapid Publications, 2013, vol. 8, art. 13010. doi: 10.2971/jeos.2013.13010

16. Harizanov O., Harizanova A. Development and investigation of sol-gel solutions for the formation of TiO2 coatings. Solar Energy Materials and Solar Cells, 2000, vol. 63, no. 2, pp. 185–195. doi: 10.1016/S0927-0248(00)00008-8

PICTURES

Fig. 1. Dependence of surface tension (a) and viscosity (b) from the degree of titanium dioxide sol dilution with ethanol in the composition of the ink

Fig.2. The dependence of reflection index on the wavelength of normally incident optical radiation onto the homogeneous surface: 1 – SiO2 glass, 2 –TiO2 film on glass surface SiO2 (fused silica)

Fig. 3. The dependence of refractive index of nanocrystalline TiO2 film, deposited on the substrate surface, on the wavelength

ig. 4. A picture of deposited and dried titanium-oxide ink drop performed on the Biolam M-1 LOMO microscope

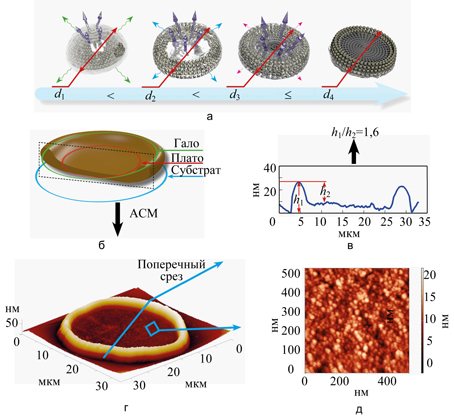

Fig. 5. The mechanism of drop transformation from liquid to solid state at the deposition by inkjet printing. The model of ink drop drying and its turning into a solid structure (a); the relief model of obtained structure (b); the AFM image of obtained structure (c); cross-section profilogram of obtained image(d); the topography of plateau surface for dried-up drop obtained on AFM (d)

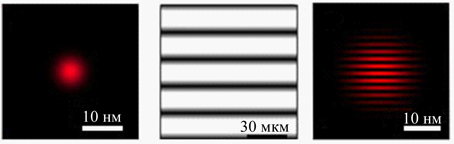

Fig. 6. Model (a, b, c) and photos of experiment (d, e, f) for laser beam passing through a diffraction grating: (a) and (d) – a laser beam that has not passed through a diffraction grating; (b) and (e) – the model gratings obtained by depositing the structures by means of the inkjet printing; (c)and (e) – diffraction patterns of the model and real experiment

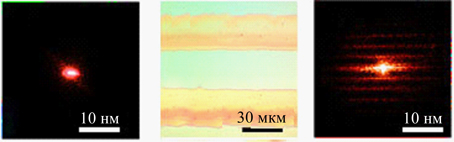

Fig. 7. Photograph of the encoded holographic image reconstruction